The Role of Robotics in Transforming Industrial Workplaces

The Rise of Robotics in Industry

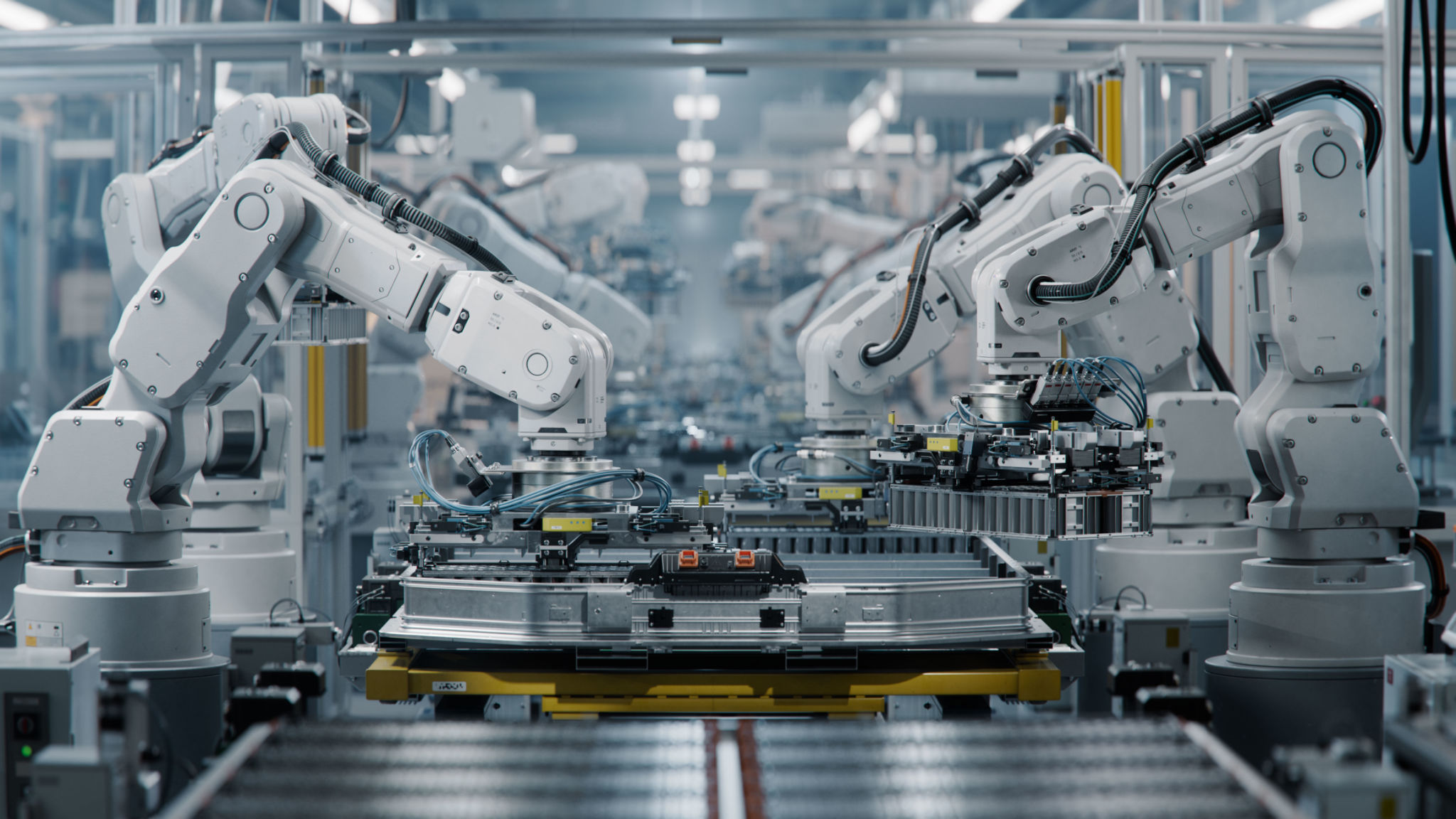

In recent years, robotics has played an increasingly transformative role in industrial workplaces. The integration of advanced robotic systems has not only enhanced productivity but also revolutionized the way industries operate. The adoption of robotics is driven by the need for efficiency, precision, and safety, making it a game-changer for businesses worldwide.

Robots are designed to perform repetitive tasks with high accuracy and speed, freeing human workers from mundane duties and allowing them to focus on more complex and creative tasks. This shift is particularly evident in manufacturing, where robotics has significantly reduced production times and costs.

Enhancing Productivity and Efficiency

The use of robotics in industrial settings has led to a remarkable increase in productivity. Robots can work tirelessly without breaks, which means that production lines can operate continuously, maximizing output. Furthermore, robots are equipped with advanced sensors and AI algorithms that enable them to adapt to different tasks and environments, further enhancing their utility.

Industries that have embraced robotics have reported not only higher production rates but also improved product quality. The precision with which robots operate reduces the likelihood of errors, ensuring that products meet high standards consistently.

Cost Reduction Through Automation

While the initial investment in robotic systems can be substantial, the long-term cost savings are significant. Automation reduces the need for manual labor, lowering labor costs and minimizing the risk of human error. Additionally, robots can work in hazardous environments, reducing the need for safety measures and insurance costs associated with human workers.

Improving Workplace Safety

One of the most significant benefits of robotics in industrial workplaces is the enhancement of safety. Robots can perform dangerous tasks that would pose risks to human workers, such as handling hazardous materials or operating heavy machinery. By taking over these roles, robots help reduce workplace accidents and injuries.

The use of collaborative robots, or cobots, further enhances safety by working alongside humans. These robots are equipped with safety features that allow them to interact with human workers safely, making them an ideal solution for environments where complete automation is not feasible.

Facilitating Innovation and Adaptation

Robotics is not just about replacing human labor; it’s about enabling innovation and adaptation in industrial processes. The flexibility of robotic systems allows industries to quickly adapt to changing market demands and technological advancements. This adaptability is crucial in maintaining a competitive edge in today's fast-paced global economy.

The Future of Robotics in Industry

As technology continues to advance, the role of robotics in industrial workplaces is expected to grow even more significant. Innovations such as machine learning and artificial intelligence are making robots smarter, more intuitive, and capable of performing a broader range of tasks.

The future will likely see more collaborative efforts between humans and robots, leveraging the strengths of both to create a more efficient and innovative industrial environment. As industries continue to embrace these technologies, the potential for growth and transformation is virtually limitless.