How Robotics is Revolutionizing Industrial Safety in Plano

Introduction to Robotics in Industrial Safety

In recent years, robotics has significantly transformed industrial safety, particularly in progressive cities like Plano. As companies strive to protect their workforce and optimize operations, the integration of robotic technology is becoming increasingly prevalent. This shift is not only enhancing safety measures but also boosting efficiency and productivity across various industries.

The Role of Robotics in Hazardous Environments

One of the primary benefits of robotics in industrial settings is their ability to operate in hazardous environments. Robots can perform tasks that are dangerous for humans, such as handling toxic substances or working in extreme temperatures. By taking on these risky jobs, robots reduce the likelihood of accidents and injuries.

In industries like chemical manufacturing and mining, where hazardous conditions are common, robots are invaluable. They are equipped with sensors and advanced technologies that allow them to navigate and perform tasks with precision, ensuring safety and reliability.

Enhancing Workplace Safety

Robots are not only used for hazardous tasks but also play a crucial role in enhancing overall workplace safety. They can be programmed to perform repetitive tasks with high accuracy, minimizing the risk of human error. This precision is essential in sectors such as automotive manufacturing, where even a small mistake can lead to significant safety hazards.

Robotics and Real-Time Monitoring

Another significant advantage of robotics in industrial safety is their ability to provide real-time monitoring and data collection. Robots equipped with cameras and sensors can continuously monitor work environments, detecting potential safety threats before they become critical issues.

This capability allows companies to implement proactive safety measures, addressing problems before they escalate. Real-time data also enables more informed decision-making, leading to improved safety protocols and standards.

Training and Workforce Adaptation

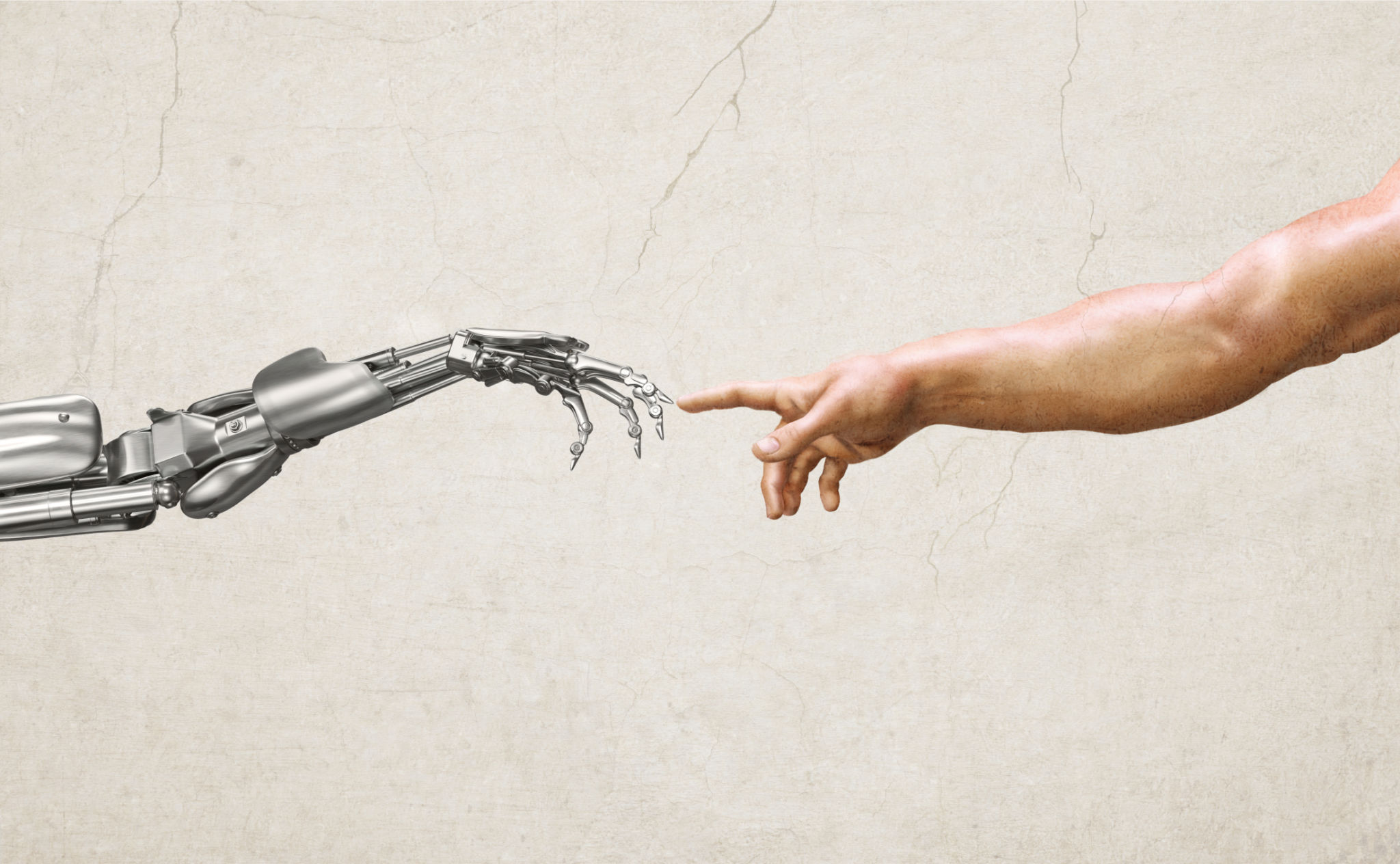

As robotics becomes more integrated into industrial settings, workforce adaptation and training are essential. Employees must be trained to work alongside robots, understanding their functions and limitations. This collaboration between humans and robots is key to maximizing safety and efficiency.

Economic Benefits of Robotics in Safety

Beyond safety improvements, robotics also offers significant economic benefits. By reducing workplace accidents, companies can decrease costs related to medical expenses, legal fees, and lost productivity. Moreover, robots can work around the clock without fatigue, leading to increased output and profitability.

This economic advantage makes robotics an attractive investment for companies looking to stay competitive in today's fast-paced industrial landscape.

Future Prospects

Looking ahead, the role of robotics in industrial safety is poised to expand even further. Advances in artificial intelligence and machine learning are expected to enhance robots' capabilities, making them even more effective in ensuring workplace safety.

As these technologies evolve, Plano is likely to continue leading the way in adopting and integrating robotics into industrial operations, setting a benchmark for safety standards worldwide.