Case Study: Success Stories of Robotics Implementations in Plano Factories

Introduction to Robotics in Manufacturing

In recent years, the integration of robotics within manufacturing has revolutionized the industry, offering improved efficiency, precision, and safety. Plano, a city known for its technological advancements, has become a hub for factories embracing this transformation. This case study highlights some of the remarkable success stories of robotics implementations in Plano factories.

As factories face increasing demands for quality and speed, robotics provides a solution by automating repetitive tasks, reducing human error, and boosting productivity. The following examples illustrate how factories in Plano have successfully implemented robotics to drive success.

The Automotive Industry

The automotive sector in Plano has seen significant benefits from robotic automation. One factory, specializing in electric vehicle components, utilized robotic arms to streamline the assembly process. By automating the welding and material handling tasks, the factory not only increased production speed but also improved the safety conditions for its workers. The precision offered by robots reduced errors and minimized material wastage.

Moreover, the integration of advanced robotics allowed for more flexibility in production lines, enabling the factory to quickly adapt to changes in design and demand. This adaptability has given the factory a competitive edge, allowing it to respond swiftly to market needs.

Electronics Manufacturing

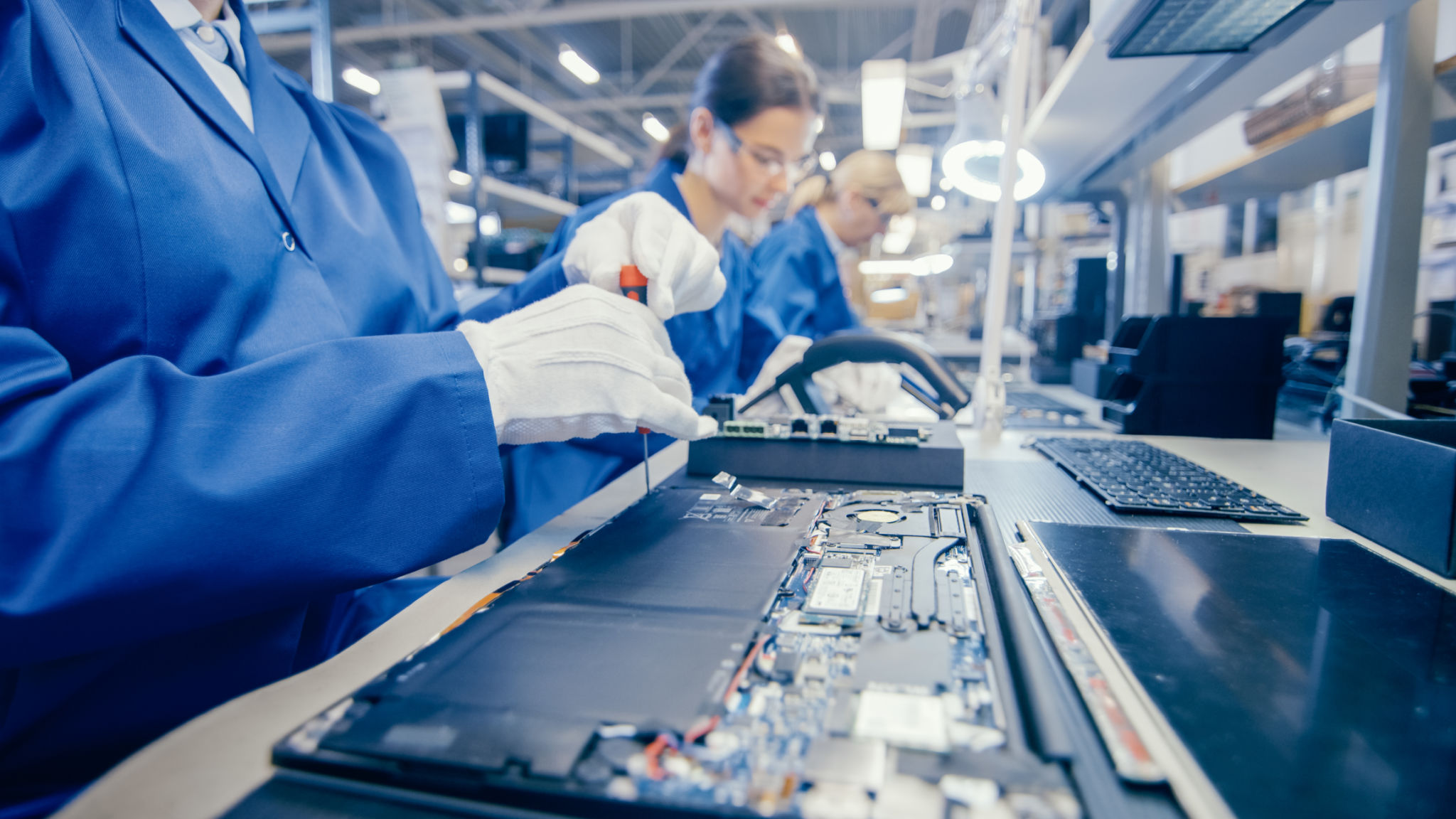

In the electronics manufacturing sector, a Plano-based factory achieved remarkable success by incorporating robotics into its operations. The implementation of automated systems for assembling circuit boards resulted in a significant reduction in production time and an increase in output. With robots handling intricate tasks previously managed by human workers, the factory experienced a surge in precision and quality control.

This transition not only enhanced efficiency but also allowed human workers to focus on more complex tasks that require critical thinking and problem-solving skills. As a result, the workforce became more engaged and productive, contributing to the factory's overall success.

Food Processing Industry

The food processing industry in Plano has also benefited from robotic technology. A local food processing plant implemented robots to handle packaging and sorting tasks. This move improved hygiene standards by minimizing human contact with food products and significantly increased throughput.

The introduction of robotics in this sector also led to a reduction in operational costs as robots operated around the clock without fatigue. The plant noted a substantial decrease in errors related to packaging, ensuring that products met rigorous quality standards consistently.

Key Takeaways

The success stories of robotics implementations in Plano factories highlight several key benefits:

- Increased Efficiency: Robots streamline operations, resulting in faster production times.

- Enhanced Quality Control: Precision tasks are handled with greater accuracy, reducing errors.

- Improved Safety: Automation reduces the risk of injuries associated with manual labor.

- Cost Reduction: Operational costs decrease as robots operate continuously without breaks.

As technology continues to advance, the integration of robotics into manufacturing processes is expected to expand further. Plano's factories serve as a testament to the transformative power of robotics in enhancing production capabilities and driving industrial success.